Bayanin Sirri: Sirrinka yana da matukar mahimmanci a gare mu. Kamfaninmu yayi alkawarin kar a bayyana keɓaɓɓun bayananku ga kowane fallasa tare da izini na bayyananne.

A halin yanzu, babban dubawa na gama yadin substrate ya rufe binciken gani, kayan aiki na lantarki (kayan aiki) masu dubawa da bincike na lantarki.

Bayyanar bayyanar subsic substrates a kai a kai ko na peccopy bracks na gani, akasarin da ya hada da fasa, ramuka, scrates a kan saman karfe Layer, peeling, scrates a kan lahani na m. Bugu da kari, girman bayyanawa na substrates, kauri daga ƙarfe Layer, Warfafawa (Cambera) na substrates, kuma daidaitawar hoto na substrate surfrate ne da ake bukata. Musamman don amfani da blip-guntu bonding, babban abin hawa mai yawa, an buƙaci warpage gaba ɗaya ya zama ƙasa da 0.3% na girma.

A cikin 'yan shekarun nan, tare da ci gaba da ci gaba na samar da fasaha na kwamfuta da fasahar sarrafa hoto, masana'antun masana'antu suna ci gaba da aiki da fasaha game da fasaha da haɓaka masana'antar masana'antu , da hanyoyin ganowa da kayan aiki dangane da hangen nesa na inji sun sannu a hankali don inganta ingancin samfurin kuma inganta yawan amfanin ƙasa. Saboda haka, aikace-aikacen hangen nesa mai dubawa na kayan aiki zuwa ga gano yadin yumbu na iya inganta ingancin yumbu kuma yana rage farashin aikin daidai.

Abubuwan da ke da kayan aikin na substic substrate galibi suna nufin karfin waya na ƙarfe Layer, wanda ke nuna ingancin kunshin kayan aiki mai zuwa (ƙarfi da aminci, da sauransu) . Da haɗin karfin yanki substrates da aka shirya ta hanyoyi daban-daban yana da bambanci sosai, kuma tsarin yanki na itace da aka shirya ta hanyar haɗin kai tsaye tsakanin ƙarfe na ƙarfe da kuma substrate, kuma karfin hadaya yana da yawa. A cikin yumbu substrate an shirya shi da ƙarancin zafin jiki (kamar DPC Substrate), Thean Der Der Waalal da ƙarfi da yawa tsakanin ƙarfe Layer da substrate na yadudduka ƙasa ne.

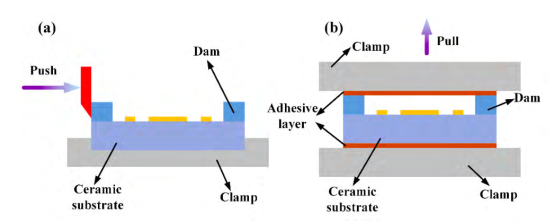

Hanyoyin gwaji don ƙarfin ƙarfe na ƙarfe a saman substrate sun haɗa da:

1) Hanyar tef: tef yana kusa da farfajiya na ƙarfe Layer, kuma roba ta birgima a kai don cire kumfa a cikin bonding a farfajiyar. Bayan seconds 10, cire tef ɗin tare da tashin hankali daɗaɗɗen ƙarfe, kuma gwada ko an cire ƙarfe Layer daga substrate. Hanyar tef ita ce hanyar gwaji mai cancanta.

2) Welding Waya Hanyar Waya: Zaɓi waya mai ƙarfe tare da diamita na 0.5mm ko 1.0mm, Weld kai tsaye a kan ƙarfe na subting, sannan a auna ƙarfin jan ƙarfe tare da tashin hankali mita.

3) Hanyar ƙarfi mai ƙarfi: Layer Layer a farfajiya subes (yanke) cikin 5mm ~ 10mm tube don gwada ƙarfin saiti. Ana buƙatar saurin saurin zama 50mm / min da mita na ma'aunin sau 10 / s.

Abubuwan da ke cikin thermal na substrate sun haɗa da halayen da ke aiki, juriya, juriya, ƙarancin ƙarfi da juriya na zafi. Yaki substrate galibi yana taka rawar gani a cikin marufi na na'urori, don haka aikin ƙirar sa shine muhimmiyar fasaha. Juriya mai zafi ya yi gwaje-gwaje ko singin yumbu ana warwatsa shi kuma an lalata shi a babban yanayin zafi, ko disaminating, da foaming ko goge ko disaming ko disaminating, da kuma cire ciki a rami ta hanyar rami ta cikin rami ya kasa.

Yin amfani da yanayin zafi na substrate substrate ba kawai ya danganta da yanayin yanayin sararin samaniya na kayan halitta (da kuma dangantaka da dangantaka da ke dubawa na kayan (Interface Contfferring Restaancessance). Sabili da haka, tsayayya da tsayayya da thermal (wanda zai iya auna juriya na jikin mutum da kuma jure yanayin da Multi-Layer) na iya kimanta yanayin yadin da yake substrate.

Ayyukan lantarki na substic substrate galibi yana nufin ko murfin ƙarfe a gaban da baya na substrate ne (ko ingancin na ciki ta hanyar rami na ciki yana da kyau). Saboda ƙananan diamita na cikin rami na yanki na DPC substrate, a lokacin da aka cika ramuka a cikin electiplating (mai kyau, saurin allura (adadi, arha ) gaba daya ana iya amfani dashi don kimanta ta hanyar ingancin ramin substrate.

Aikin tattake na substrate galibi yana nufin weldability da tsananin iska (iyakance ga substam substrate). Don inganta ƙarfin haɗin kai na good waya, wani ƙarfe na ƙarfe tare da kyakkyawan walwala kamar AU ko gun an lalata shi gaba ɗaya ko kuma padting pad) don hana oxidation ourdation da kuma inganta ingancin jigon kai. Weldability an auna shi gaba daya daga aluminum waya injunan injuna da mitoci na tashin hankali.

Guntu an saka shi a kan 3D yanki na yanki subrate kogon, kuma an rufe kogon tare da farantin murfin (karfe ko gilashi) don gane kayan kunshin naúrar. Airwar iska mai tsauri da kayan walda kai tsaye yana tantance iska ta sama, da kuma iska ta zama daban-daban hanyoyin daban daban. Ana amfani da subshin yumɓu guda uku na substrate da yawa don gwada haɓakar iska da tsari, da kuma manyan hanyoyin suna yin kumfa gas kumfa da ƙimar ƙirar gas.

Dogara yafi Gwada canje-canjen wasan kwaikwayon na yadudduka a cikin wani takamaiman yanayi (high zazzabi, lalata zazzabi, rawar jiki mai zafi, girgiza babban zafin jiki, famara mai zafi, Corroon juriya, lalata lalata masara, matsananciyar jijiyoyin ƙasa, da sauransu. Bincika sauti microscope (Sam) da mai gano X-ray (X-ray) don nazarin walda da lahani da lahani.

LET'S GET IN TOUCH

Bayanin Sirri: Sirrinka yana da matukar mahimmanci a gare mu. Kamfaninmu yayi alkawarin kar a bayyana keɓaɓɓun bayananku ga kowane fallasa tare da izini na bayyananne.

Cika ƙarin bayani don hakan na iya shiga tare da ku cikin sauri

Bayanin Sirri: Sirrinka yana da matukar mahimmanci a gare mu. Kamfaninmu yayi alkawarin kar a bayyana keɓaɓɓun bayananku ga kowane fallasa tare da izini na bayyananne.